Top Stories

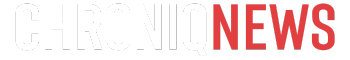

Chinese Researchers Slash Microchip Defects by 99% with New Tech

BREAKING: Chinese researchers have developed a groundbreaking technology that can reduce microchip manufacturing defects by a staggering 99%. This urgent advancement in semiconductor production was confirmed by a team led by Professor Peng Hailin from Peking University, Tsinghua University, and HKU (University of Hong Kong), marking a pivotal moment for the industry.

The innovative technique utilizes cryo-electron tomography (cryo-ET), a method typically reserved for biological studies, to freeze the microchip development process in real-time. This allows researchers to visualize and analyze defects that have long plagued the delicate lithography stage of microchip production.

Currently, during photolithography, tiny circuit patterns are “printed” onto silicon wafers using light. However, this intricate process can lead to significant issues, as even a minuscule 30-nanometre particle can render a chip unusable. Until now, manufacturers struggled to identify the exact causes of these defects, which can result in massive financial losses.

In a remarkable breakthrough, the research team rapidly froze the chemical process at 32°F (–175°C), capturing the behavior of photoresist polymers during development. Their findings revealed that approximately 70% of these polymers fail to dissolve properly, leading to the formation of clumps that cause defects. By implementing two effective adjustments—raising the bake temperature and altering the rinse process—they successfully reduced defect counts on 12-inch (30.5 cm) wafers by over 99%.

This urgent development not only enhances the quality of semiconductor manufacturing but also positions China as a formidable player in the global chip industry. As demand for advanced technology surges, this innovation could significantly impact tech production, ensuring more reliable and efficient microchips.

Next, industry experts are watching closely to see how quickly manufacturers will adopt these techniques, which promise to revolutionize the microchip landscape. With the potential for increased yields and reduced costs, this breakthrough could lead to a new era in semiconductor production.

Stay tuned for further updates on this developing story as the implications for technology and the economy unfold.

-

Top Stories1 week ago

Top Stories1 week agoMarc Buoniconti’s Legacy: 40 Years Later, Lives Transformed

-

Sports3 weeks ago

Sports3 weeks agoSteve Kerr Supports Jonathan Kuminga After Ejection in Preseason Game

-

Politics3 weeks ago

Politics3 weeks agoDallin H. Oaks Assumes Leadership of Latter-day Saints Church

-

Business3 weeks ago

Business3 weeks agoTyler Technologies Set to Reveal Q3 2025 Earnings on October 22

-

Science3 weeks ago

Science3 weeks agoChicago’s Viral ‘Rat Hole’ Likely Created by Squirrel, Study Reveals

-

Lifestyle3 weeks ago

Lifestyle3 weeks agoKelsea Ballerini Launches ‘Burn the Baggage’ Candle with Ranger Station

-

Lifestyle3 weeks ago

Lifestyle3 weeks agoDua Lipa Celebrates Passing GCSE Spanish During World Tour

-

Health3 weeks ago

Health3 weeks agoRichard Feldman Urges Ban on Menthol in Cigarettes and Vapes

-

Entertainment3 weeks ago

Entertainment3 weeks agoZoe Saldana Advocates for James Cameron’s Avatar Documentary

-

Health3 weeks ago

Health3 weeks agoCommunity Unites for Seventh Annual Mental Health Awareness Walk

-

Sports3 weeks ago

Sports3 weeks agoPatriots Dominate Picks as Raiders Fall in Season Opener

-

Business3 weeks ago

Business3 weeks agoMega Millions Jackpot Reaches $600 Million Ahead of Drawings