Science

Innovative AI System Identifies Welding Defects, Promotes Sustainability

Researchers at Örebro University in Sweden have unveiled a groundbreaking AI system designed to detect welding defects with remarkable accuracy. Developed by Rajesh Patil and Professor Magnus Löfstrand, this innovative technology aims to significantly reduce material waste and support sustainable manufacturing practices.

The AI system employs advanced imaging techniques, referred to as “smart eyes,” to analyze welds in real-time. By identifying defects early in the production process, it allows manufacturers to rectify issues before they escalate, thereby saving resources and minimizing environmental impact. This development comes at a crucial time when industries are increasingly pressured to adopt more sustainable practices.

Enhancing Efficiency in Manufacturing

Welding is a critical process in many manufacturing sectors, including automotive and construction. Traditionally, detecting defects can be time-consuming and often requires extensive manual inspection. The implementation of this AI system promises to streamline operations, improving efficiency and reducing costs associated with rework or material wastage.

According to the researchers, the AI’s ability to analyze welding quality in real-time can lead to a reduction in defects by as much as 30%. This substantial decrease not only enhances the durability and safety of welded structures but also supports manufacturers in achieving their sustainability goals.

Impact on Industry and Environment

The implications of this technology extend beyond cost savings and operational efficiency. By minimizing material waste, the AI system contributes to a more environmentally friendly production process. The manufacturing sector is responsible for a significant portion of global waste, and innovations like this can play a pivotal role in addressing sustainability challenges.

Professor Löfstrand emphasized the importance of integrating AI into traditional manufacturing processes. He stated, “Our goal is to create a future where smart technologies enhance human capabilities while reducing the ecological footprint of production.”

As industries around the world adopt these advanced technologies, the potential for widespread change becomes evident. This AI system not only represents a step forward in manufacturing efficiency but also showcases the transformative power of technology in promoting sustainability. The ongoing research and development at Örebro University highlight the critical role of academic institutions in driving innovation that meets both economic and environmental needs.

In conclusion, the development of this AI system marks a significant milestone in the quest for sustainable manufacturing. With its ability to detect welding defects effectively, it positions manufacturers to thrive in an increasingly competitive and environmentally conscious market. The collaboration between researchers and the industrial sector will be essential to fully realize the potential of this technology and its impact on global manufacturing practices.

-

Science3 months ago

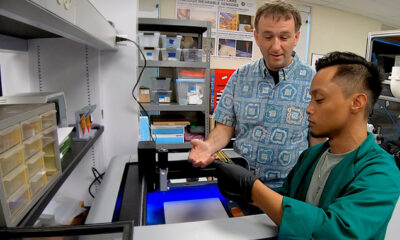

Science3 months agoUniversity of Hawaiʻi Joins $25.6M AI Project to Monitor Disasters

-

Business3 months ago

Business3 months agoForeign Inflows into Japan Stocks Surge to ¥1.34 Trillion

-

Entertainment2 months ago

Entertainment2 months agoHudson Williams Gains Popularity as Breakout Star on Heated Rivalry

-

World3 months ago

World3 months agoBoeing’s Merger with McDonnell Douglas: A Strategic Move Explained

-

Science2 months ago

Science2 months ago$1.25M Grant Advances Hawaiʻi’s Real-Time Hazard Monitoring

-

Entertainment3 months ago

Entertainment3 months agoSydney Sweeney Embraces Body Positivity Amid Hollywood Challenges

-

Top Stories3 months ago

Top Stories3 months agoBOYNEXTDOOR’s Jaehyun Faces Backlash Amid BTS-TWICE Controversy

-

World3 months ago

World3 months agoFrench Film Explores Group Therapy in ‘Group – The Schopenhauer Project’

-

Top Stories3 months ago

Top Stories3 months agoUrgent Farewell: Joleen Chaney Leaves Legacy at KFOR

-

Top Stories3 months ago

Top Stories3 months agoMarc Buoniconti’s Legacy: 40 Years Later, Lives Transformed

-

Lifestyle4 months ago

Lifestyle4 months agoKelsea Ballerini Launches ‘Burn the Baggage’ Candle with Ranger Station

-

Top Stories3 months ago

Top Stories3 months agoCarson Wentz Out for Season After Shoulder Surgery: Urgent Update